+8617856445471

Roller Coating Workshop

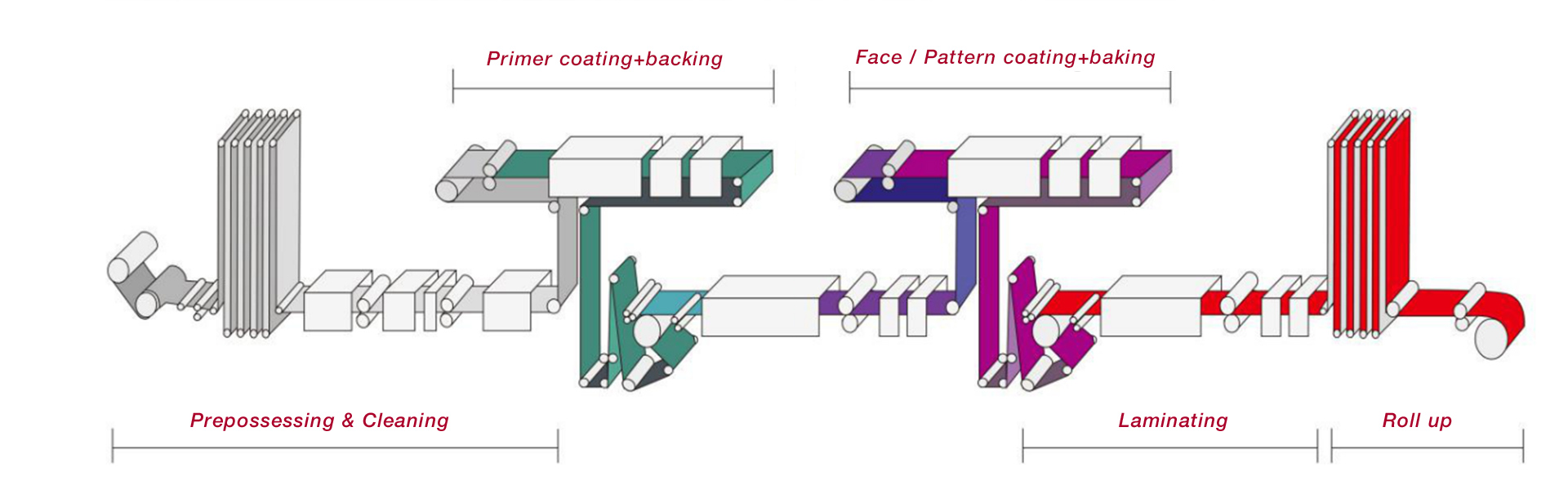

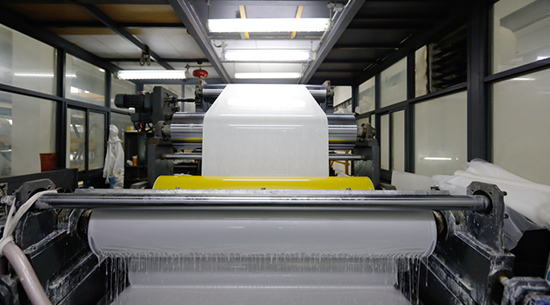

Roller Coating is pre-coated with paints on continuous aluminum coils by rollers with or without patterns.

With latest roller coating line, we coat aluminum coil with mono-color or various special patterns to imitate the natural pattern of stone, woodgrain fabric, metallic, brush finish and etc.

The roller coated coils can be cut, bended and assembled into facade cladding panels, or be fabricated into corrugated panels with specific equipment.

Six-coat Five-bake precision roll coating production line:

①6 coats are formed at one time with a running speed of 30 m/min (high production efficiency);

②coating thickness difference <±1μm (high equipment precision)

③Adopt German Siemens industrial control equipment (high operational stability)

④Integrate advanced catalytic combustion waste gas treatment process/RTO (low environmental impact)

"Excellent Flatness:

The aluminum internal stress has been fully relieved during pre-coating by high- temperature baking when it is still flat, it is fabricated without being welded and unlike spray-coated panel, once fabricated the roller coating panel won't be baked again. All the above result in least distortion and excellent panel flatness.

Environment friendly:

Unlike spray coating, roller coating does not create paint mist. And compared with 50% paint usage by spray coating, roller coating's paint usage is over 95%.

Excellent Color Consistency:

Least coating thickness tolerance, least baking temperature tolerance and continuous coating on coil contribute to the excellent color consistency of roller coating aluminum panels.

Exquisite finish:

The roller coating aluminum panel is pre-coated by way of pressing printing with non- granular, non-porous, stainless fine and smooth finish.

Various Patterns Available:

Similar to roller printing technology, the roller coating aluminum panels are available with various vivid patterns including stone, timber and etc. by using different rollers engraved with different patterns."